PanX

Designed with an innovative multi grid modeling approach, PanX delivers rapid, accurate and scalable simulations that capture the complex thermal and mechanical behaviors of 3D printed components. Trusted by industry leaders in aerospace, automotive and medical devices, PanX empowers engineers to shorten prototyping cycles, reduce build failures and consistently achieve first-run print success.

PanX, the state-of-the-art additive simulation platform from PanOptimization, is now available in the North America through DSI.

Industry Leading Accuracy & Detail

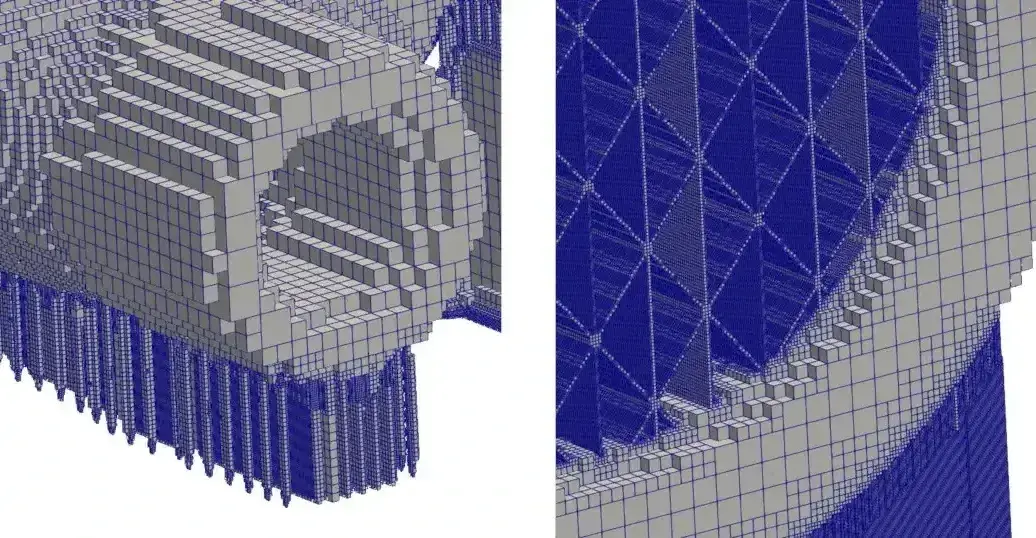

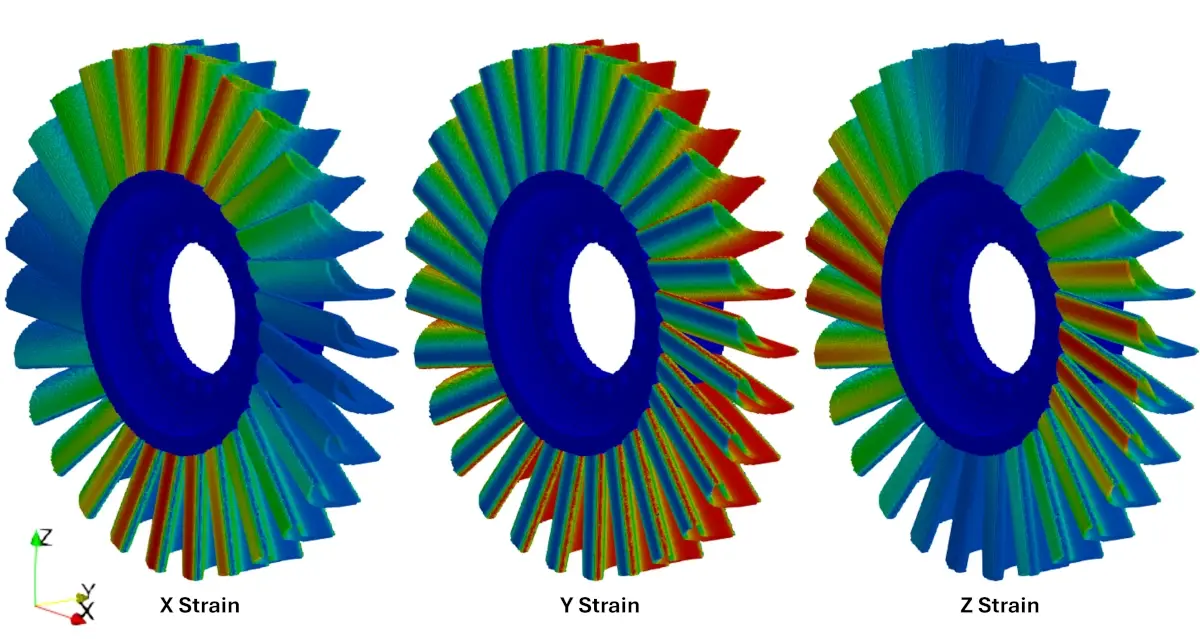

Resolve fine geometric details and achieve precise thermal and mechanical predictions. PanX's Multi-Grid Modeling and feature-aware meshing capture essential build characteristics, allowing accurate modeling of full build plates, complex interactions, and real-world process parameters.

Unmatched Simulation Speed

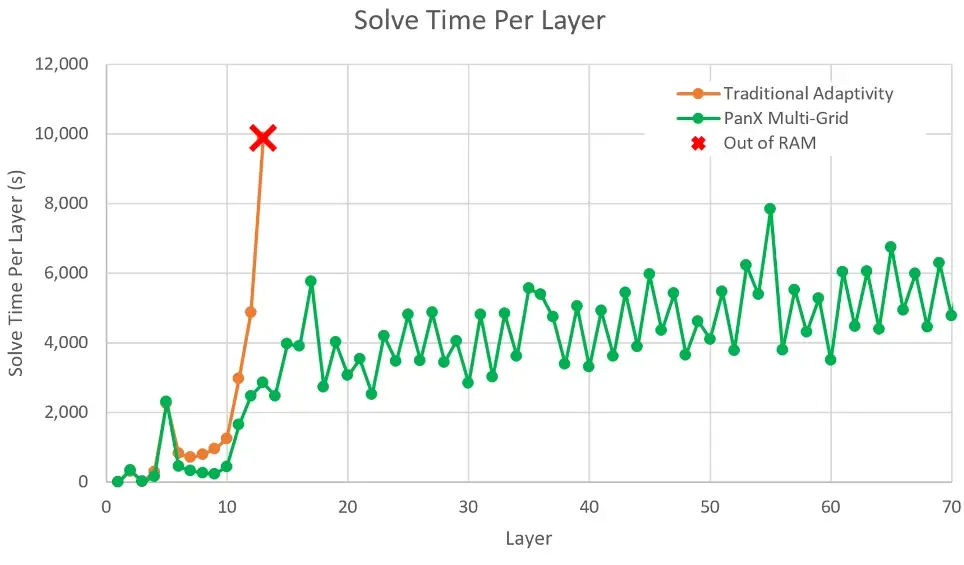

Simulate complex additive geometries 100x faster than legacy FEA solutions. PanX scales linearly, eliminating bottlenecks and significantly reducing simulation runtimes—turn days into hours and accelerate your product development.

Built for Complex, Large-Scale AM

PanX is engineered to handle additive manufacturing simulations of unprecedented size and complexity. Efficient meshing techniques allow simulations on standard engineering hardware without simplifying geometries, enabling seamless simulation and optimization of even the most challenging AM parts.

PanX is Accurate.

Experience unmatched precision as PanX captures intricate details, simulates full build plates, and delivers high-fidelity thermal predictions with real process parameters.

PanX is Scalable.

Seamlessly model any geometry, no matter the size or complexity, with performance that scales linearly leaving traditional tools behind.

PanX is Fast.

Accelerate your workflow with simulations up to 100x faster than legacy FEA, cutting complex build times to a fraction of reality.

PanX is Effecient.

Enjoy powerful, high-quality simulations on everyday engineering laptops or desktops, optimizing resources without compromise.

Key Features & Benefits

-

Multi-Grid Modeling: Retain critical transient details and eliminate traditional simulation slowdowns.

-

Feature-Aware Meshing: Optimize computational resources by intelligently focusing on essential geometric features.

-

Full Build Plate Accuracy: Precisely simulate thermal and mechanical interactions across entire build plates.

-

Flexible Calibration: Simplify setup with a single calibration per material-machine-process combination.

-

Detailed Surface Resolution: Clearly visualize build lines, stress concentrations, and subtle deformations to inform your design decisions.

-

Optimization Capabilities: Employ adjoint sensitivity-driven optimization to quickly enhance your AM designs and reduce support structure needs.

.png?width=900&height=780&name=hx_small_composite3%20(1).png)

Let's get started

Provide some quick info about your current needs so we can start the conversation about how PanX can transform your manufacturing ops!